The store will not work correctly in the case when cookies are disabled.

Notes| General |

| Note | The max. load current must not be exceeded by the total current of all connected conductors. |

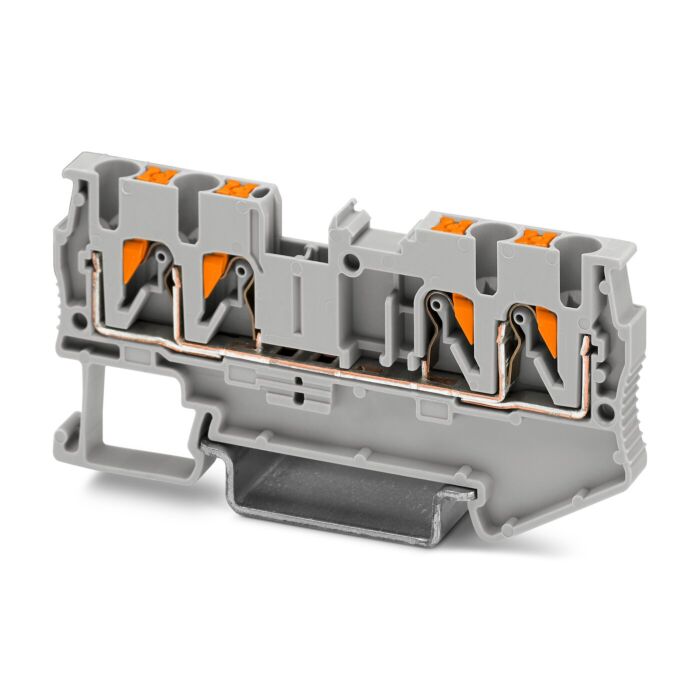

Product properties| Product type | Multi-conductor terminal block |

| Area of application | Railway industry |

| Machine building |

| Plant engineering |

| Process industry |

| Number of connections | 4 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics |

| Overvoltage category | III |

| Degree of pollution | 3 |

Electrical properties| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 0.77 W |

Connection data| Number of connections per level | 4 |

| Nominal cross section | 2.5 mm² |

| 1 level |

| Stripping length | 8 mm ... 10 mm |

| Internal cylindrical gage | A3 |

| B2 |

| Conductor cross section solid | 0.14 mm² ... 4 mm² |

| Cross section AWG | 26 ... 12 |

| Conductor cross section flexible | 0.14 mm² ... 2.5 mm² |

| Conductor cross section, flexible [AWG] | 26 ... 14 |

| Flexible conductor cross section flexible (ferrule, w/o plastic sleeve) | 0.14 mm² ... 2.5 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 0.14 mm² ... 2.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² |

| Nominal current | 24 A (with 2.5 mm² conductor connection cross section) |

| Maximum load current | 28 A (with 4 mm² conductor cross section, rigid) |

| Nominal voltage | 800 V |

| Nominal cross section | 2.5 mm² |

| 1 level Connection cross sections directly pluggable |

| Conductor cross section solid | 0.34 mm² ... 4 mm² |

| Flexible conductor cross section flexible (ferrule, w/o plastic sleeve) | 0.5 mm² ... 2.5 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 0.34 mm² ... 2.5 mm² |

Ex data| Rated data (ATEX/IECEx) |

| ATEX certificate | PTB 09 ATEX 1111 U |

| IEC Ex certificate | IECEx PTB 10.0021 U |

| Identification | II 2 G Ex eb IIC Gb |

| Operating temperature range | -60 °C ... 110 °C |

| Ex-certified accessories | 3030514 D-ST 2,5-QUATTRO |

| 3030815 ATP-ST QUATTRO |

| 3036602 DS-ST 2,5 |

| 1204517 SZF 1-0,6X3,5 |

| 3022276 CLIPFIX 35-5 |

| 3022218 CLIPFIX 35 |

| Bridge data | 19 A / 2.5 mm² |

| Ex temperature increase | 40 K (19 A / 2.5 mm²) |

| Rated voltage | 500 V |

| for bridging with bridge | 550 V |

| - At bridging between non-adjacent terminal blocks | 352 V |

| - At cut-to-length bridging | 220 V |

| - At cut-to-length bridging with cover | 275 V |

| - At cut-to-length bridging with partition plate | 550 V |

| Rated insulation voltage | 500 V |

| Ex level General |

| Rated current | 19 A |

| Maximum load current | 23 A |

| Contact resistance | 1.14 mΩ |

| Ex connection data General |

| Nominal cross section | 2.5 mm² |

| Rated cross section AWG | 14 |

| Connection capacity rigid | 0.14 mm² ... 4 mm² |

| Connection capacity AWG | 26 ... 12 |

| Connection capacity flexible | 0.14 mm² ... 2.5 mm² |

| Connection capacity AWG | 26 ... 14 |

Dimensions| Width | 5.2 mm |

| End cover width | 2.2 mm |

| Height | 35.3 mm |

| Height NS 35/15 | 44.3 mm |

| Height NS 35/7,5 | 36.8 mm |

| Length | 72.2 mm |

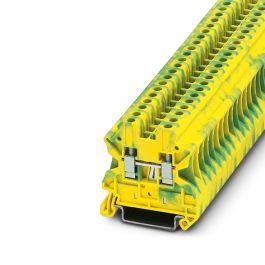

Material specifications| Color | gray |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

Electrical tests| Surge voltage test |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Temperature-rise test |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Short-time withstand current 4 mm² | 0.48 kA |

| Result | Test passed |

| Power-frequency withstand voltage |

| Test voltage setpoint | 2 kV |

| Result | Test passed |

Mechanical properties| Mechanical data |

| Open side panel | Yes |

Mechanical tests| Mechanical strength |

| Result | Test passed |

| Attachment on the carrier |

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 1 N |

| Result | Test passed |

| Test for conductor damage and slackening |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross section/weight | 0.14 mm² / 0.2 kg |

| 2.5 mm² / 0.7 kg |

| 4 mm² / 0.9 kg |

| Result | Test passed |

Environmental and real-life conditions| Aging |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Spectrum | Service life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions |

| Ambient temperature (operation) | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

Standards and regulations| Connection in acc. with standard | IEC 60947-7-1 |

Mounting| Mounting type | NS 35/7,5 |

| NS 35/15 |

In order for the Goods to be eligible for a return, please make sure that:

The Goods were purchased in the last 14 days

The Goods are in the original packaging

The Goods were not used or damaged